In recent years, more and more air cleaners have been used in living and working environments.

For houses, the sale of air cleaners have remarkably increased with a catch phrase of collecting mite, mold, dust and pollen that are said to be the cause of allergy.

In work places, there is a problem of smoking, and many companies provide smoking spots, in which air cleaners play an important role.

In addition, air cleaners are used in the production shop of precision instrument and semiconductor that are easily damaged by dust.

An air cleaner has a construction in which relatively large dust in the air is caught by a filter installed all over the cleaner and the dust of micro-size passing through the filter is charged by discharge electrode and attracted by a dust collecting filter charged by reverse electrode. As a result, the air blown out of the air cleaner is clean without dirty particle.

There are two types of discharge electrodes to be used in an air cleaner. The one is of a needle type and the other is of a wire type, and NIPPON TUNGSTEN supplies the wire type electrode made of tungsten. Our discharge tungsten wire began with the production of charge wire for PPC and, through the improvement of basic properties of charge wire, has reached the quality of charged wire for air cleaner (referred to as ionized wire) having an excellent durability. In addition, we are producing platinum-plated drawn wire (patented, Hei-78882) as a new product of discharge wire so as to improve the quality.

We are offering ionized wires having various types of surface treatment as shown in Table-1 however, in the case of plated wires, they have a limit in diameter due to the characteristics of production process.

| Type | Feature |

|---|---|

| Graphite tungsten wire | Black tungsten wire whose surface is covered with carbon |

| White tungsten wire | Graphite tungsten wire whose carbon surface is finished to white |

| Mirror-finished tungsten wire | White tungsten wire whose surface is further polished to be smooth having metallic luster, suitable for negative charge type copying machine and the like which require a stable discharge at the initial stage |

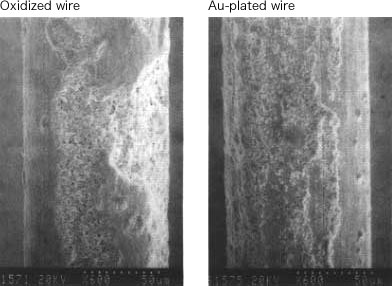

| Oxidized tungsten wire | White tungsten wire whose surface is forcedly oxidized, classified into two types with color, gold and dark blue, used widely |

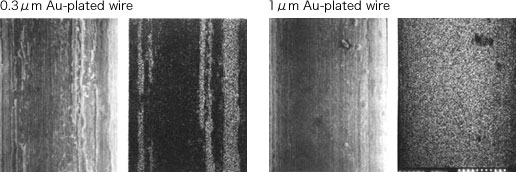

| Gold-plated tungsten wire | White tungsten wire whose surface is plated with gold by approximately 0.3オm thickness, used widely same as the oxidized tungsten wire |

| Gold-plated drawn tungsten wire | Gold-plated tungsten wire which is plated thick and drawn several times so as to improve the gold layer in denseness and fitness to tungsten |

| Platinum-plated tungsten wire | Gold-plated tungsten wire to which platinum plating is added, especially suitable for positive charge type copying machine |

| Platinum-plated drawn tungsten wire | Platinum-plated tungsten wire which is plated thick and drawn several times so as to improve the platinum layer in denseness and fitness to tungsten, especially suitable for positive charge type copying machine |