Jigs made of resin such as PEEK are often used as transport guides for electronic component inspection equipment from the aspects of insulation and cost.

However, resin jigs wear out due to insufficient hardness in the inspection process of a large number of electronic components, resulting in inspection failures due to poor positioning accuracy. In addition, maintenance such as fixture replacement is required more frequently and reduced productivity becomes a problem.

Our ceramic fixtures for electronic component inspection equipment solve these problems.

However, resin jigs wear out due to insufficient hardness in the inspection process of a large number of electronic components, resulting in inspection failures due to poor positioning accuracy. In addition, maintenance such as fixture replacement is required more frequently and reduced productivity becomes a problem.

Our ceramic fixtures for electronic component inspection equipment solve these problems.

Benefits of using ceramics

In the inspection process of electronic components, our ceramic jigs provide optimal inspection jigs by proposing materials suitable for your requirements and using our high-precision processing technology. This system contributes to the realization of stable inspection quality over a long period of time by preventing the deterioration of transfer and positioning accuracy due to wear of the fixture.

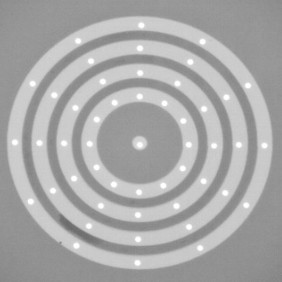

(1) Ceramic microfabrication processing and special processing cases

Example of micro holes on silicon nitride

Example of micro holes on silicon nitride Example of micro holes and groove machining on zirconia

Example of micro holes and groove machining on zirconiaHole diameter: 0.08mm, groove width: 0.25mm

(2) Ceramic and metal bonding

In inspection fixtures for electronic components, ceramics can be combined only where insulation and wear resistance are required.Compared to one-piece ceramic products, damage caused by human error when installing fixtures can be suppressed and significant cost reductions can be expected.

SUS + zirconia + carbide combination example

SUS + zirconia + carbide combination exampleExample application

- Peripheral components for semiconductor manufacturing

- Electronic component inspection jig

- Measuring jig

- Transport guides, etc.

- Electronic component inspection jig

- Measuring jig

- Transport guides, etc.