Cemented carbide is a hard metal and a sintered composite material of metal carbides (Group IV, V and VI in periodic table) with ferrous metals, such as Fe, Co and Ni, as binders. WC-Co based alloys have excellent mechanical characteristics so that they are commonly known as cemented carbides. Every alloy has features of stable physical properties and high strength, also with good high-temperature hardness. For cutting tools and other applications, we also provide WC-Co based alloys added with TiC or TaC to increase oxidation-resistance.

Furthermore, cemented carbides with Ni as a binder phase have stronger corrosion-resistance than those with Co and can be used as non-ferromagnetic materials by controlling the solution amount of W into Ni. We can also provide WC-Ni-Cr based alloys progressed in corrosion-resistance by adding Cr.

Furthermore, cemented carbides with Ni as a binder phase have stronger corrosion-resistance than those with Co and can be used as non-ferromagnetic materials by controlling the solution amount of W into Ni. We can also provide WC-Ni-Cr based alloys progressed in corrosion-resistance by adding Cr.

Fig.1 Structure of Cemented Carbide

Manufacturing Method of Cemented Carbide (Powder Metallurgy)

Cemented carbides are manufactured by the unique method, called powder metallurgy.

It is the method of making forms by sintering the pressed powder.

As tungsten carbide (WC), mainly used in cemented carbides, is very difficult to be melt and formed like iron because of its high melting point (2900 degrees Celsius), cemented carbides are manufactured by this method.

It is the method of making forms by sintering the pressed powder.

As tungsten carbide (WC), mainly used in cemented carbides, is very difficult to be melt and formed like iron because of its high melting point (2900 degrees Celsius), cemented carbides are manufactured by this method.

Main Features of Cemented Carbide

Main features of cemented carbide are superb hardness (80 to 94 in HRA), having larger degree of strength than ceramics (more than 2GPa (200kg/mm2) in bending strength), large Young's modulus (3 times larger than iron), great specific gravity (twice as much as iron) and so on.

Cemented Carbide with corrosion-resistance

Nowadays, cemented carbides are adopted in many applications that need high corrosion-resistance. We have been developing and providing various materials through our research about corrosion-resistant property.

Cemented Carbide of Super-fine Grains

Applying super-fine WC grains, we made it possible for our products, such as NT die cutters and mold components, to have high-strength and high-hardness.

Physical Properties of NITTANLOY Wear and Impact

Physical Properties of NITTANLOY Wear and Impact

| JIS Class | CIS 019D | NITTNLOY | Density (g/cm3) | Hardness HRA | Bending strength (GPa) | Comprssive strength (GPa) | Modulus of elasticity (GPa) | Poisson's ratio | Young's modulus (GPa) | Coefficient of thermal expansion (x10-6/K) | Coefficient of thermal couduntivity (W/(m*K)) | Applications |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| V10 | VM-20 | G1 | 14.6 | 91.5 | 1.8 | 5.5 | 640 | 0.19 | 637 | 5 | 80 | For its outstanding resistance to wear, the material is used for mechanical seals, rings, nozzles, guides, bushings, inspection gauges, and others. |

| V20 | VM-30 | G2 | 14.9 | 91 | 2.2 | 5 | 630 | 0.2 | 630 | 5.1 | 75 | |

| V30 | VM-40 | G3 | 14.7 | 89.5 | 2.6 | 4.7 | 580 | 0.21 | 579 | 5.3 | 71 | The material is used for mechanical articles requiring resistance to wear. |

| G20 | 14.5 | 89 | 2.5 | 4.4 | 560 | 0.22 | 559 | 5.5 | 67 | |||

| V40 | VM-50 | G30 | 14.2 | 88 | 3.2 | 4.3 | 550 | 0.22 | 549 | 5.7 | 67 | |

| G40 | 14 | 87.5 | 3.2 | 4.2 | 540 | 0.22 | 539 | 5.9 | 65 | |||

| V50 | VM-50 | G50 | 13.8 | 86.5 | 3.2 | 3.8 | 510 | 0.23 | 510 | 6.2 | 63 | |

| Fine grain grades | VF-20 | FN10 | 14.5 | 92.5 | 2.5 | 5.3 | 570 | 0.24 | 570 | 5.5 | - | The material can be adopted for use in trimming blades, die cutters, and other sharp-edged cutters. |

| VF-30 | FN20 | 14.3 | 91.5 | 2.5 | 5.1 | 550 | - | 549 | 5.8 | 71 | ||

| VF-30 | FN30 | 13.9 | 90.5 | 3.1 | 4.7 | 540 | - | - | 6 | 67 | ||

| VF-40 | FN40 | 13.7 | 90.5 | 3.1 | 4.7 | 530 | - | 530 | 6.2 | 64 | ||

| Extra fine frain grades | VF-40 | SF30 | 13.8 | 92 | 4 | 4.8 | 545 | - | 510 | 6 | 67 | The material is expected to bring a longer service life in super-fine particle alloy applications. |

| VF-40 | SF50 | 13.4 | 90.5 | 3.8 | 3.8 | 490 | - | 460 | 6.4 | 63 | For its high toughness, the material is suited for use in thin blades and trimming blades. | |

| Reference SKH material | 8.7 | 83 | 3.4 | 3.7 | 210 | 0.3 | - | 11 | 21 | |||

Physical Properties of Corrosion-resistant and Non-Magnetism NITTANLOY

| Property | CIS 019D | NITTANLOY | Composition | Density (g/cm3) | Hardness HRA | Bending strength (GPa) | Compressive strength (GPa) | Modulus of elasticity (GPa) | Poisson's ratio | Young's modulus (GPa) | Coefficient of thermal expansion (x10-6/K) | Coefficient of thermal conductivity (W/(m*K)) | Applications |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Corrosion resistance | NM-60 | NM15 | WC-Ni -Cr | 14 | 86.5 | 2.5 | 3.5 | 530 | 0.21 | 530 | 6.4 | 50 | Non-magnetic die, Blanking dies |

| NM-40 | NR8 | WC-Ni | 14.8 | 89.5 | 2.3 | 4.2 | 600 | 0.20 | 600 | 5.7 | 75 | general applications requiring resistance against corrosion | |

| NF-40 | NR11 | WC-Ni -Cr-Mo | 13.5 | 90.0 | 2.4 | 4.6 | 530 | 0.21 | 530 | 6.1 | 63 | ||

| UM-10 | RCCL | WC-TiC -TaC | 14.7 | 94.0 | 1.0 | 3.6 | 640 | 0.20 | 640 | 4.8 | 70 | ||

| VF-10 | RCCFN | WC-TiC -TaC | 14.6 | 95.0 (*) | 1.5 | 4.1 | 600 | 0.20 | 630 | 4.9 | 72 | Mirror-finished products, Nozzles |

NR11, RCCL and RCCFN are non-magnetic alloys

(*) HR30N

(*) HR30N

Corrosion Resistance of NITTANLOY

| Solu- tion | Hydrofluoric acid | Hydrochloric acid | Sulfuric acid | Nitric acid | Sodium hydroxide | Ammonium nitrate | Hydrogen peroxide water | Pure water | Acetic acid | Phosphoric acid | Citric acid | Seawater | Ethanol Methanol | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Concentration (%) | 20 | 5 | 10 | 20 | 5 | 10 | 5 | 10 | 10 | 10 | 100 | 10 | 10 | 10 | 100 | 100 | |

| Temperature (˚C) | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 22 | |

| NITTAN- LOY | G2 | B | C | C | D | D | B | B | B | C | E | A | B | D | B | B | A |

| G3 | B | C | C | D | E | C | B | B | C | E | A | B | D | B | B | A | |

| NR8 | B | B | B | B | B | B | B | B | C | E | A | B | B | B | A | A | |

| NR11 | A | C | B | B | B | B | A | A | A | C | A | A | B | A | A | A | |

| DUX30/40 | B | B | B | A | D | D | A | A | A | C | A | A | B | A | B | A | |

| RCCL | A | A | A | B | B | A | B | B | A | D | A | A | A | B | A | A | |

The test pieces were left alone in a solution of atmosphere for a day and then measured for decreases in weight caused by corrosion. The results were ranked as follows in accordance with DIN4851 (German industrial standard): Ranking (decrease in weight by corrosion)

A: Excellent,2.4g/m2/day or less; B: good, 24g/m2/day or less; C: fair, 72g/m2/day or less; D: poor, 240g/m2/day or less; E:absent, 240g/m2/day or less

A: Excellent,2.4g/m2/day or less; B: good, 24g/m2/day or less; C: fair, 72g/m2/day or less; D: poor, 240g/m2/day or less; E:absent, 240g/m2/day or less

NITTANLOY for Cutting Tools

| JIS Class | NITTANLOY | Composition | Density (g/cm3) | Hardness HRA | Transverse rupture strength (Gpa) | Compressive strength (Gpa) | Modulus of elasticity (Gpa) | Coefficient of thermal expansion (x10-6/K) | Coefficient of thermal conductivity (W/(m*K)) |

|---|---|---|---|---|---|---|---|---|---|

| P10 | SN10 | WC-TiC-TaC-Co | 11 | 92 | 1.6 | 4.5 | 520 | 6.5 | 29 |

| P20 | SN20 | 12.1 | 91.5 | 1.8 | 4.7 | 530 | 6 | 34 | |

| SN25 | 12.1 | 91 | 1.9 | - | - | - | - | ||

| FL37S | 12.7 | 91.5 | 2.1 | - | - | - | - | ||

| P30 | SN30 | 12.7 | 90.5 | 2 | 4.9 | 550 | 5.5 | 59 | |

| P40 | SN40 | 13.4 | 89.5 | 2.4 | 4.6 | 550 | 5.5 | 59 | |

| M10 | UN10 | WC-TiC-TaC-Co | 13.2 | 92 | 1.6 | 4.9 | 570 | 5.5 | 50 |

| M102 | 13.1 | 92.5 | 1.7 | - | - | - | - | ||

| M20 | UN20 | 13.9 | 91.5 | 1.7 | 4.8 | 560 | - | 63 | |

| M30 | UN30 | 13.7 | 90 | 2 | 4.7 | - | - | - | |

| M40 | UN40 | 13.4 | 89.5 | 2.4 | 4.3 | 530 | 5.7 | 59 | |

| K01 | UN05 | WC-TiC-TaC-Co | 14.3 | 93 | 1.7 | 6.2 | - | - | - |

| K10 | HN10 | 14.2 | 93 | 1.8 | 6.1 | - | 5.5 | 80 | |

| G1 | WC-Co | 14.6 | 92 | 1.8 | 5.5 | 640 | 5 | 80 | |

| K20 | G2 | 14.9 | 91 | 2.2 | 5 | 630 | 5.1 | 75 | |

| K30 | G3 | 14.7 | 89.5 | 2.6 | 4.7 | 580 | 5.3 | 71 | |

| Cermet | DUX30 | TiC-TaN-Ni-Mo | 6.9 | 92.5 | 1.6 | - | - | - | - |

| DUX40 | 6.5 | 91.5 | 1.8 | 3.9 | 470 | 7 | 29 |

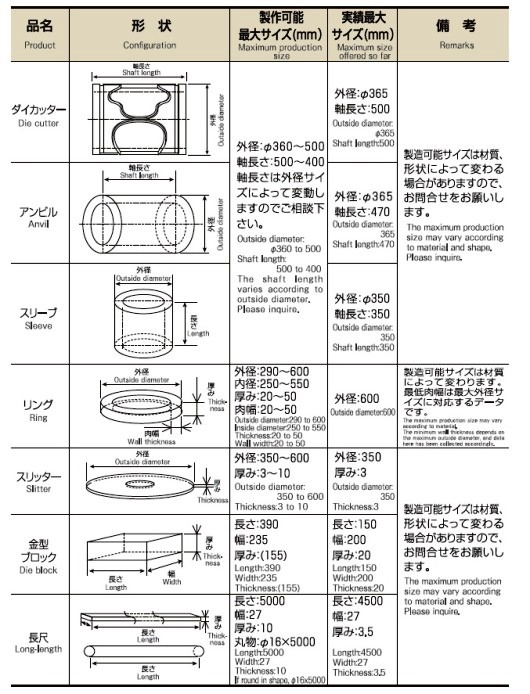

Cemented Carbide Product Maximum Production Sizes