*This is a property of our porous ceramics and means that suction is possible without covering the entire suction surface.

Advantages of porous ceramics

Are you currently experiencing any inconvenience with the suction rolls you are using?

Our porous ceramic suction rolls solve the following problems.

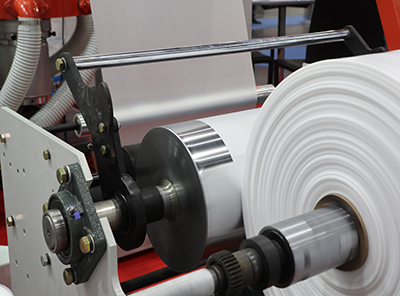

- Suction roller requiring setup for each production item

- Multiple suction rolls being required due to the difference in the contact angle and width of the workpiece for each production item

- Suction marks on thin workpieces

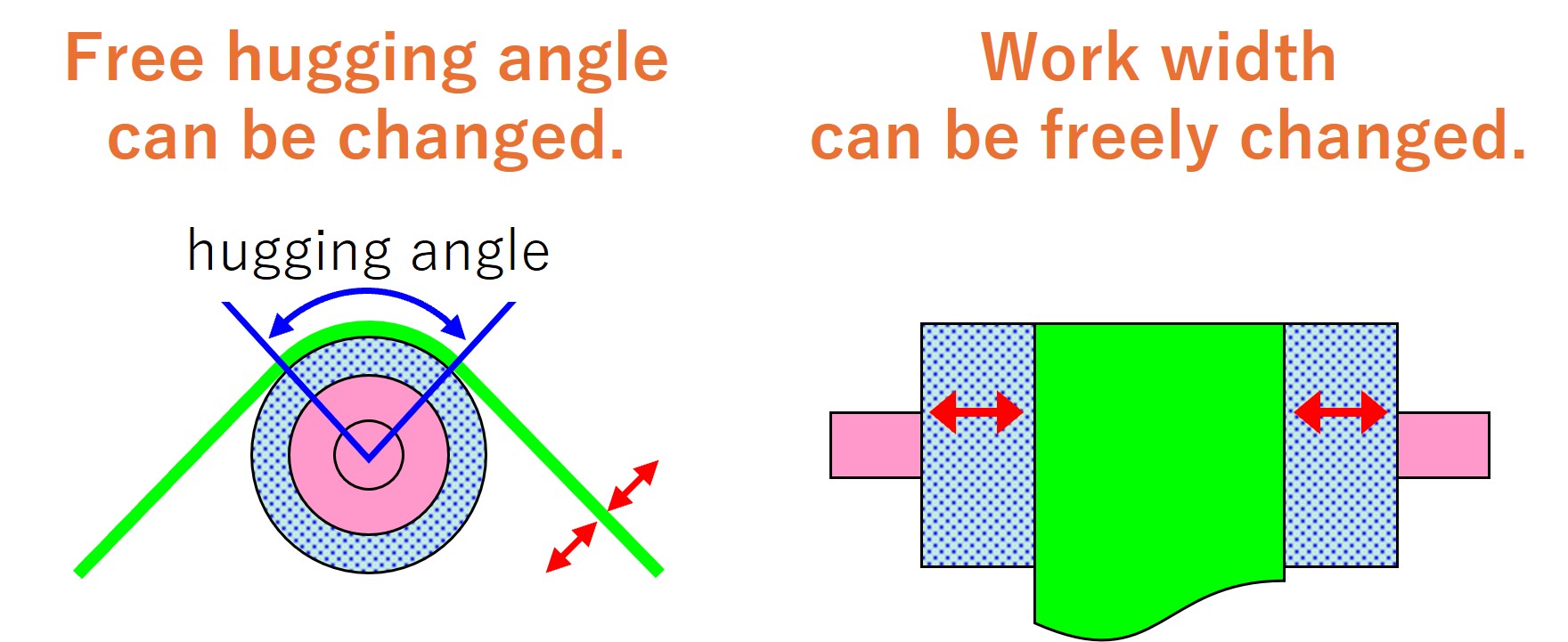

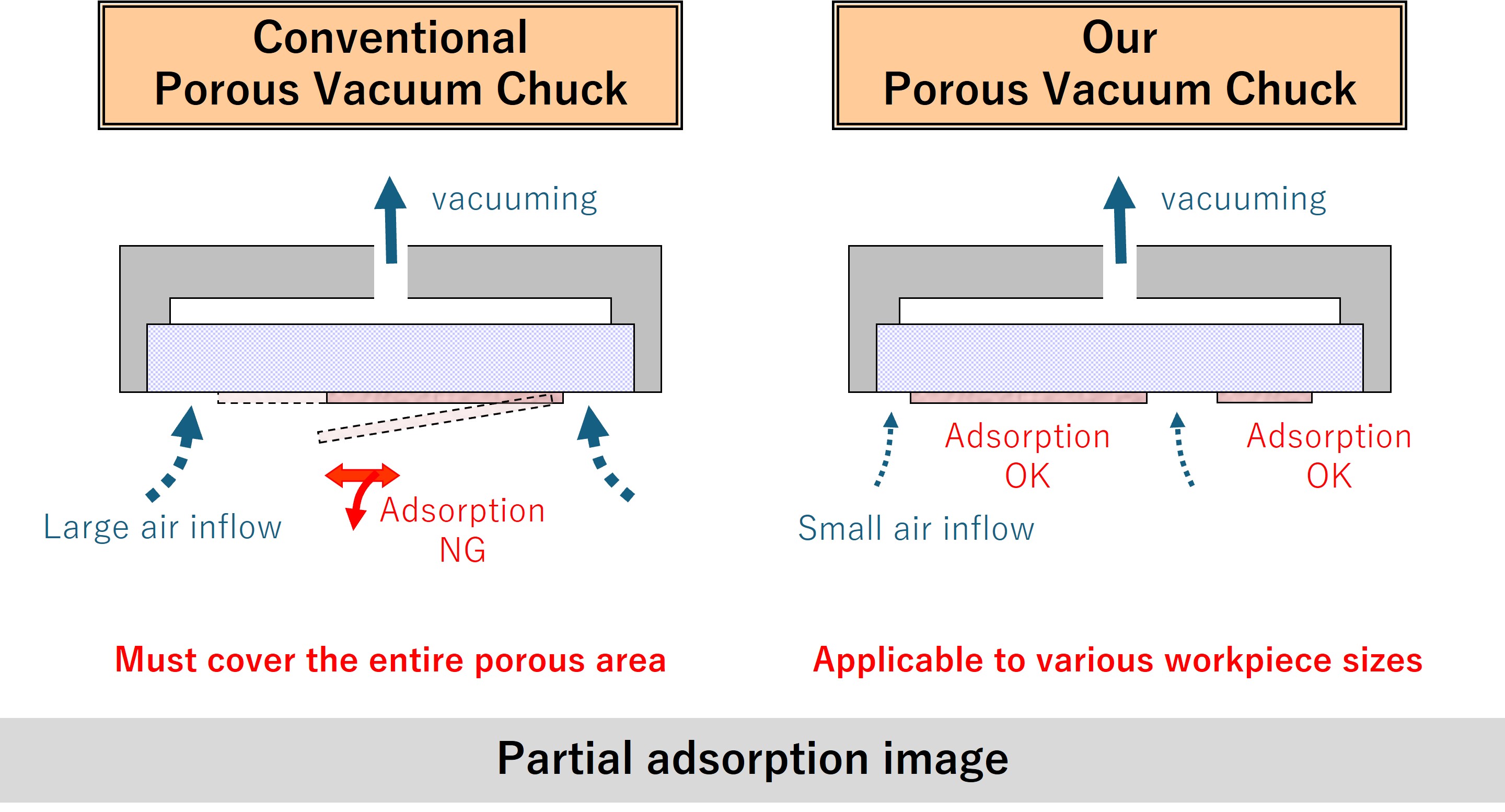

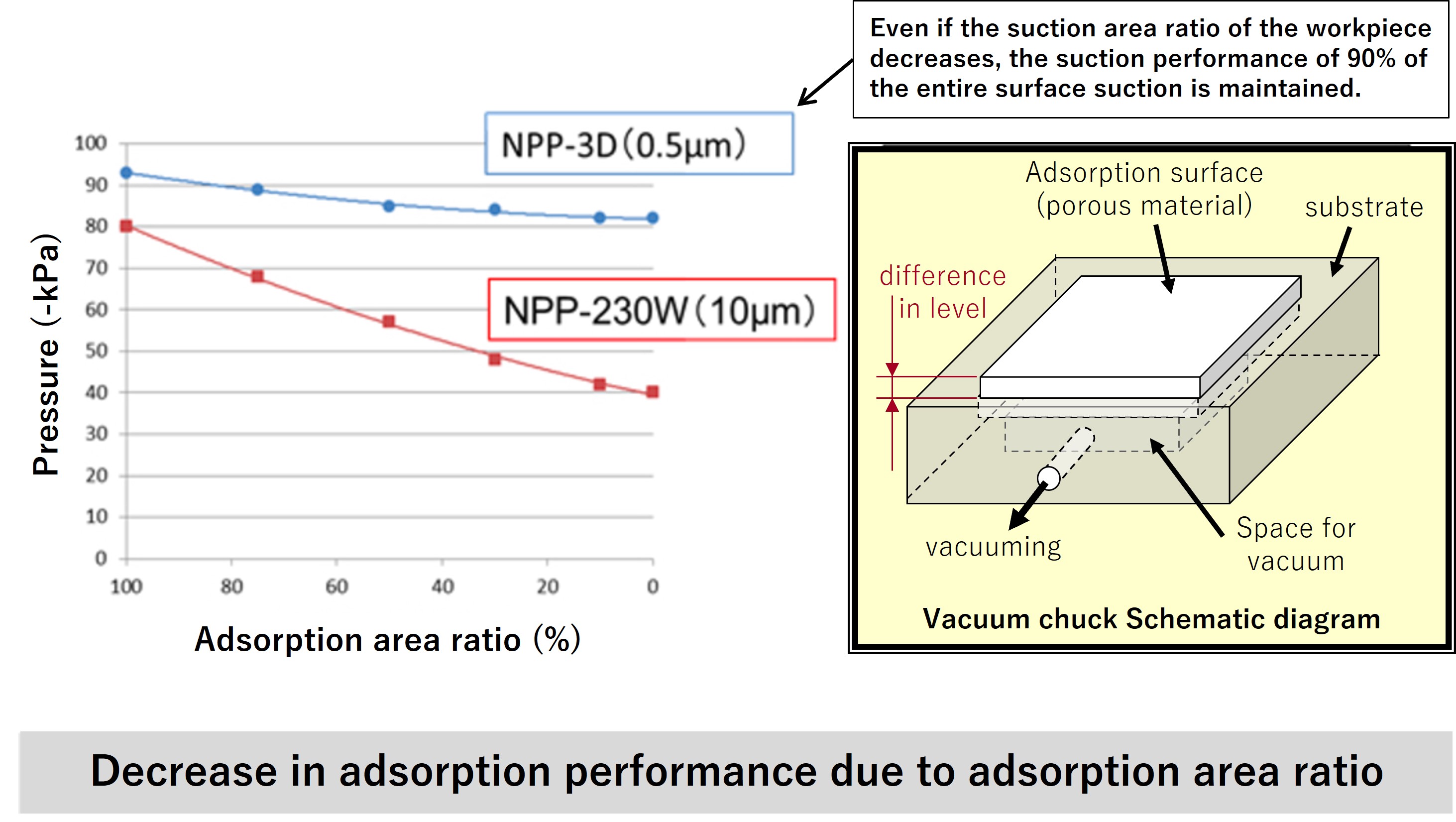

(1) Reduction of setup man-hours and number of suction rolls held by partial suction performance

- The partial suction performance allows the user to freely change the contact angle and workpiece width.

(2) Resolving faults caused by suction marks and deformation

With our porous ceramic suction rolls, you can

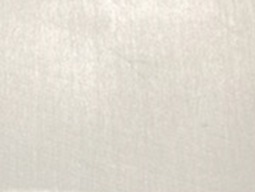

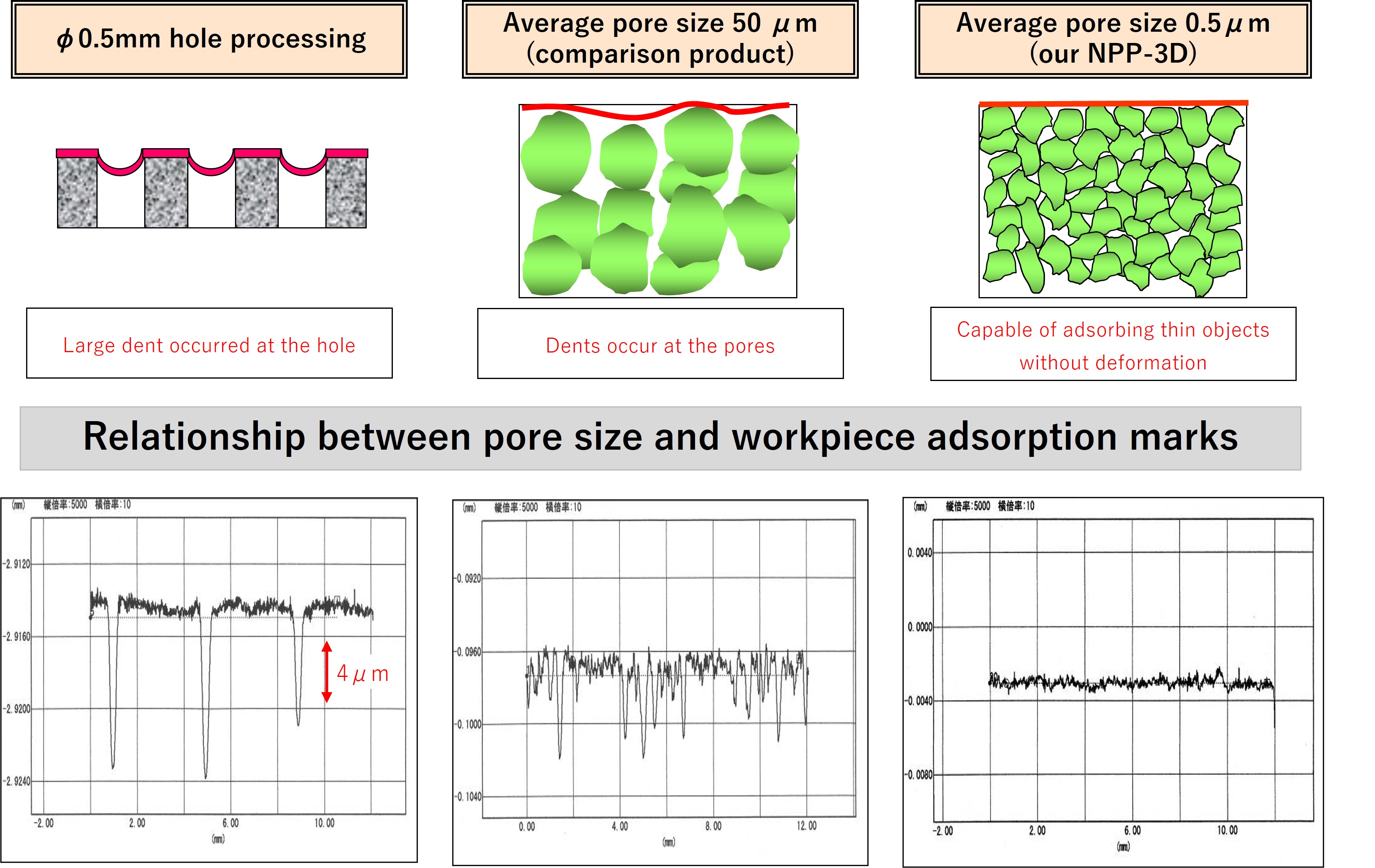

- Reduce suction marks as much as possible with the use of porous ceramic with minute pore size

- Prevent deformation of thin workpieces

Suction mark reference image

What is porous ceramic?

With conventional vacuum chucks, the suction plate was generally replaced according to the workpiece. If the vacuum chuck had a part that is not suctioned, air entered from the area and it was difficult for differential pressure to be generated, so suction force could not be achieved.

Our NPP-3D (material name) has partial suction performance and provides suction force without covering the entire chuck section, thus enabling suction without having to change the vacuum chuck setup for each workpiece.

Example application

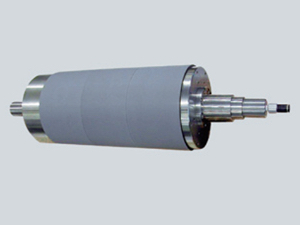

○ Suction rolls (for roll-to-toll process transport)

○ For thin-film transport

○ For pattern inspection such as for silicon wafers and films

○ For painting and printing devices

○ For suction fixing for processing

○ Other applications requiring vacuum suction

☆ Technical Briefing Sessions are available

We can also provide presentations at your company, which have been well-received at various exhibitions.

We will be explaining the differences from conventional vacuum chucks, advantages, disadvantages, and precautions for use.

☆ We have a demo machine available

We can organize an occasion where you can take a look at how the porous ceramics work as a vacuum chuck. If you wish to see a demo machine,

please include your request in the inquiry form below.