We have the best electrodes for resistance welding of non-ferrous metals such as copper, which is often found especially in automotive electrical components, to meet your needs for extending electrode life and improving productivity.

Advantages of tungsten and molybdenum electrodes

- I want to improve productivity

The characteristics of tungsten and molybdenum electrodes and their advantages in resistance welding are as follows.

| Features of tungsten and molybdenum | Benefits during resistance welding |

|---|---|

| - Excellent high-temperature hardness - Little reaction with other metal components | - Stable current density is maintained due to reduced deformation |

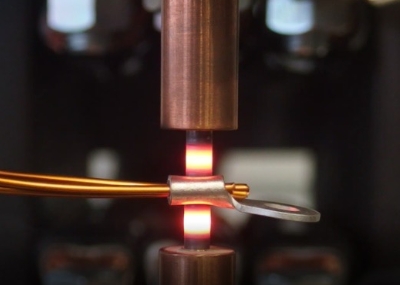

In particular, it demonstrates its performance in resistance welding of materials with low electrical resistance and high thermal conductivity (materials that do not generate heat by resistance), such as copper, and materials with surface treatment such as plating.

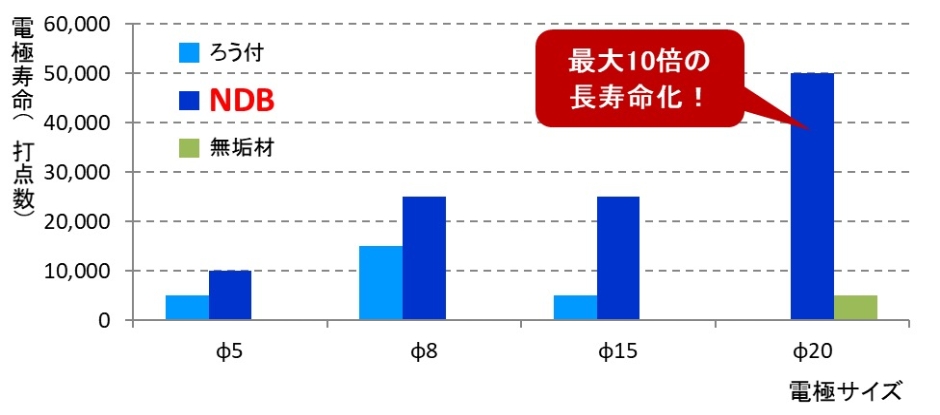

In most cases, these electrodes are joined with copper shanks. Our electrodes use our proprietary direct bonding technology called the NDB method, which is expected to extend the life of electrodes and improve productivity (shot cycle) compared to conventional brazed electrodes.

Example of electrode life comparison

Example of electrode life comparisonWhat are tungsten/molybdenum resistance welding electrodes?

We have a variety of electrode materials including tungsten, molybdenum, and tungsten composites to suit the welding material.

We can also manufacture electrodes to customer specifications, such as those bonded with copper shanks.

Example electrodes

Example electrodes

Click here for more information (detailed resources)

Resistance Welding Electrode Guidebook contains information on electrode material lineups, troubleshooting, and more

These materials are available through the following library website. Please feel free to access them.