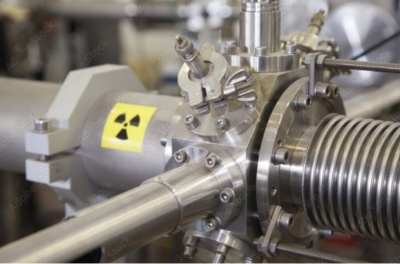

Radiation used in the industrial and medical industries must be shielded within the equipment to prevent leakage outside the equipment.

Lead (Pb) is well-known as an inexpensive material with high shielding capability, but it is increasingly regulated in various fields as an environmentally harmful material.

Our KABELLOY heavy alloy for radiation shielding has less environmental impact and higher shielding capability than lead.

Lead (Pb) is well-known as an inexpensive material with high shielding capability, but it is increasingly regulated in various fields as an environmentally harmful material.

Our KABELLOY heavy alloy for radiation shielding has less environmental impact and higher shielding capability than lead.

Benefits for customers after introducing KABELLOY heavy alloys for radiation shielding

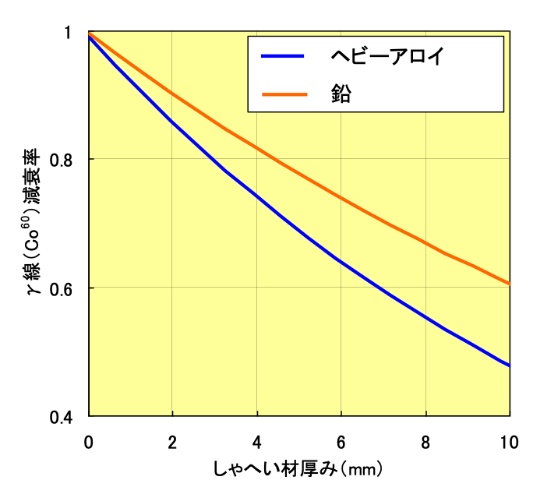

(1) High shielding capabilities, contributing to space-saving

The graph on the left shows the change in γ-ray (Co60) attenuation for various thicknesses of KABELLOY and lead when irradiated with radiation.

KABELLOY can be made approximately 30% thinner in material if the same shielding capacity as lead is required.

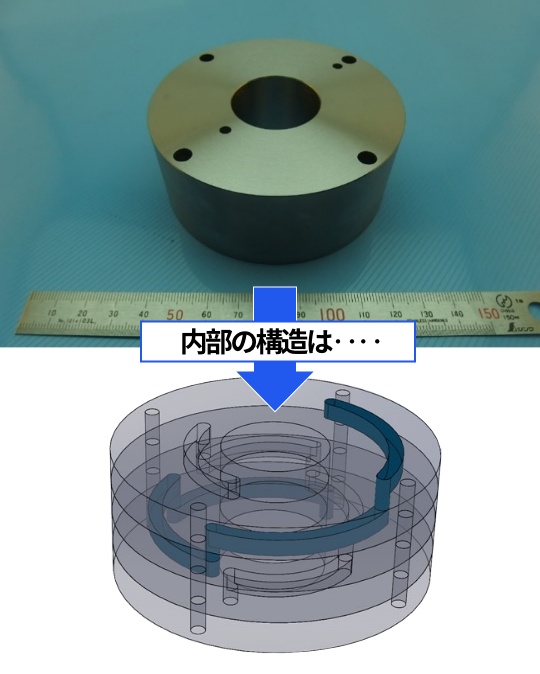

(2) Lines which coolant passes through that cannot be seen from the outside!

KABELLOY materials can be joined with each other. It can be applied to components that require various functions as well as expanding the scope of design, such as hollow materials that can only be made with a 3D printer and structures with bent cooling channels.

(3) Environmentally friendly and contributes to the SDGs

The KABELLOY material does not contain metals subject to the RoHS Directive and REACH regulations, and the environmental impact is less than that of lead.

The high radiation shielding capability also makes it possible to reduce the overall space required for the entire equipment, and the reduction in the size of the equipment enables a reduction in the number of components other than the shielding material part.

Features of the KABELLOY heavy alloy for radiation shielding

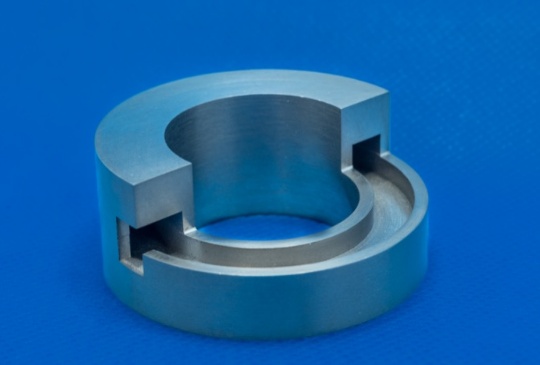

KABELLOY is a sintered alloy composed mainly of tungsten and a metal binder phase.

Compared to pure tungsten or cemented carbide, cutting is easier and can be used for complex shapes.

Some material types also have high heat resistance and mechanical properties (stretching and Young's modulus), allowing them to be used in environments where materials are subjected to stress.

Our customers are also interested in the following products:

Electrical contact materials...Electrical Contact Materials < Electrical Contact-related | Nippon Tungsten Co., Ltd. (nittan.co.jp)