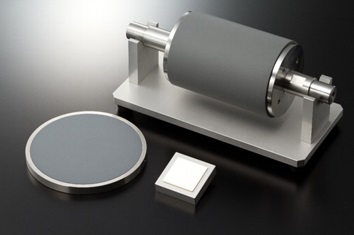

Mechanical technologies are improving every day; for example, precision components are getting smaller and functional films are getting thinner. To cope up with these rapid changes, more precise machines with higher performance abilities are required. Drawbacks associated with conventional vacuum chucks include adsorption marks and the need to change the adsorption plate depending on the size of the workpieces. However, our technology makes it possible to manufacture micro-porous ceramics that are suitable for adsorbing and transferring thin workpieces with a wide range of sizes without deformation.

Applications

- Pattern inspections on silicon wafers or films

- Transferring thin films

- Coating or printing machines

- Web handling

- Workpiece retention during processing

- Other various vacuum-adsorption applications

- Pattern inspections on silicon wafers or films

- Transferring thin films

- Coating or printing machines

- Web handling

- Workpiece retention during processing

- Other various vacuum-adsorption applications

Features of Nippon Tungsten's Porous Ceramics

- The alumina (Al2O3)-based porous medium has excellent chemical stability.

- The uniform distribution of micro-pores enables a highly smoothed surface. (Available roughness: Ra = 0.6µm)

- Our NPP-3D ceramic has a higher strength than ordinary porous ceramics.

- The main component is alumina, and it does not include metals.

- It is unlikely to cause diffused reflections or halation during image-based inspections.

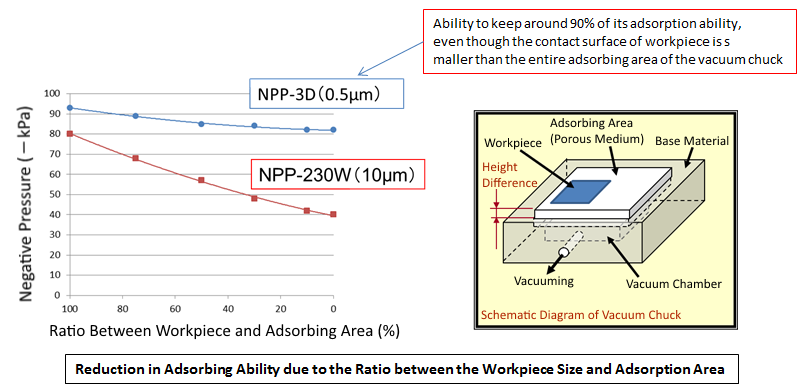

- Taking advantage of the part-adsorbing characteristics (please see below for details), it is possible to use a single vacuum chuck for various workpiece sizes.

- The uniform distribution of micro-pores enables a highly smoothed surface. (Available roughness: Ra = 0.6µm)

- Our NPP-3D ceramic has a higher strength than ordinary porous ceramics.

- The main component is alumina, and it does not include metals.

- It is unlikely to cause diffused reflections or halation during image-based inspections.

- Taking advantage of the part-adsorbing characteristics (please see below for details), it is possible to use a single vacuum chuck for various workpiece sizes.

Physical Properties of Porous Ceramics

| Product | Porosity [%] | Pore Size [μm] | Bending Strength [MPa] | Young's Modulus [GPa] | Thermal Conductivity [W/mEK] | Specific Heat [J/kgEK] | Coefficient of thermal expansion [x10−6/K] |

|---|---|---|---|---|---|---|---|

| NPP-3D | 30 | 0.5 | 90 | 90 | 12 | - | 5.7 |

| NPP-230W | 30 | 10 | 29 | 27 | 4 | 789 | 4.5 |

| Dense alumina | - | 520 | 350 | 36 | 782 | 5.7 |

Enlarged View of Porous Ceramics' Inner Structure

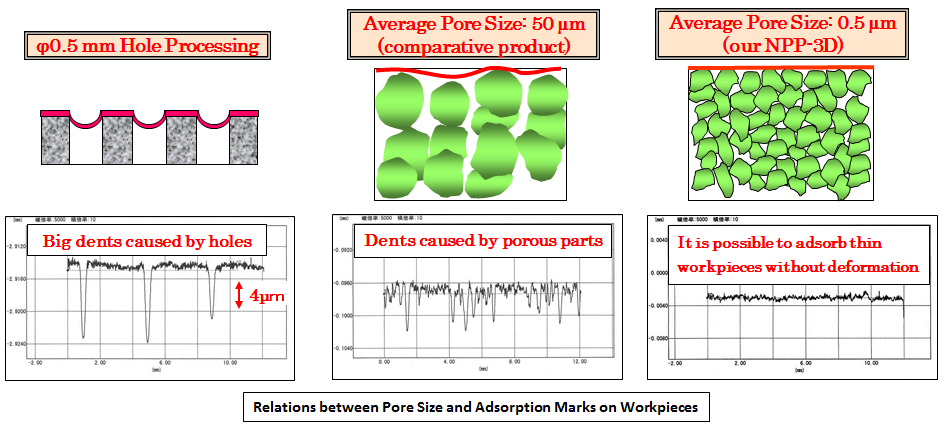

The Best Way to Solve the Problem of Adsorption Marks!

Aren't you looking for a solution for the adsorption marks that appear on workpieces?

Our NPP-3D, the porous ceramic material with micron-order-sized pores, enables adsorption and retention with few adsorption marks that are significantly reduced in size.

Our NPP-3D, the porous ceramic material with micron-order-sized pores, enables adsorption and retention with few adsorption marks that are significantly reduced in size.

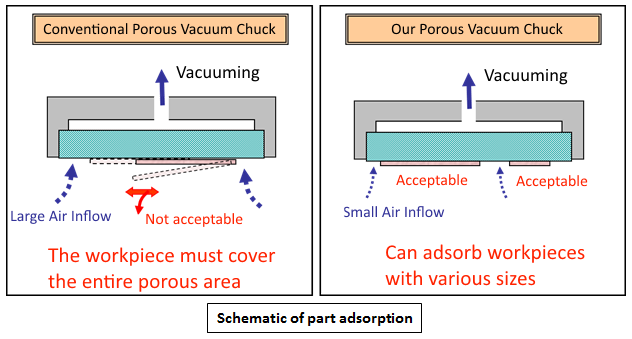

No need to change chucks!

In conventional vacuum chucks, it is necessary to change the adsorption plates depending on the workpiece size. However, our NPP-3D, a porous ceramic material with micron-order sized pores designed for efficient part adsorption, enables the use of a single vacuum chuck for various workpiece sizes, maintaining excellent adsorbing ability not only for large workpieces but also for small ones.

For Details

For further information, please contact us through the below inquiry form.