Nippon Tungsten processes materials such as tungsten, molybdenum, and copper-tungsten, and provides technological services specialized in tungsten-based welding electrodes to contribute toward improvement in productivity.

We have been the only recipient of the Technological Achievements Award for resistance welding electrodes from Japan Tungsten & Molybdenum Industries Association in the country [2013, Development of W. Mo-NDB resistance welding electrode].

We have been the only recipient of the Technological Achievements Award for resistance welding electrodes from Japan Tungsten & Molybdenum Industries Association in the country [2013, Development of W. Mo-NDB resistance welding electrode].

We published "Guidebook on Resistance Welding Electrodes for Tungsten- and Molybdenum-Based Electrodes" in July 2016.

The main contents of this guidebook are as follows:

1. Resistance Welding of Non-Ferrous Metals Such as Copper

2. Recommended Electrode Materials and Troubleshooting

3. Examples of Applications for Tungsten- and Molybdenum-Based Electrodes

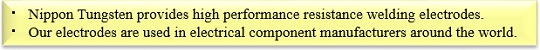

3. Lineup of Nippon Tungsten Electrode Materials and Their Characteristics

5. Response to Customer Needs

6. Compilation of Data for Reference

7. For Customers with Overseas Production Bases

For further information about this guidebook, please contact us through the below inquiry form.

The resistance welding electrodes of Nippon Tungsten

Problems in resistance welding electrodes

- We use chromium copper, but can't the lifetimes be longer?

=> Electrodes whose hardness and electrical conductivity (IACS%) are improved through thermal treatments become blunt due to the repeated heating.

- We use copper welding or copper heat caulking, but the quality is not stable.

=> The point is to have the electrode generate heat!

=> It is the high-temperature range that chromium copper/alumina dispersion copper cannot endure.

Tungsten (W), molybdenum (Mo) and their alloy electrodes deliver high performance during resistance welding/heat caulking. They are also optimal for fusing electrodes and spot electrodes.

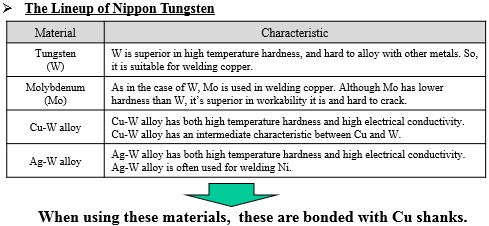

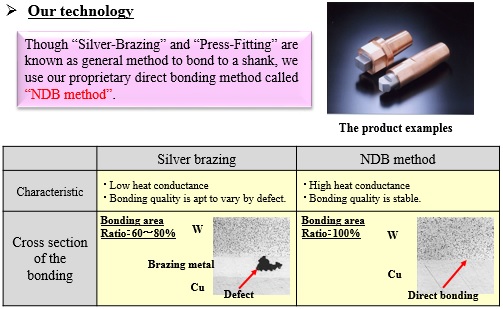

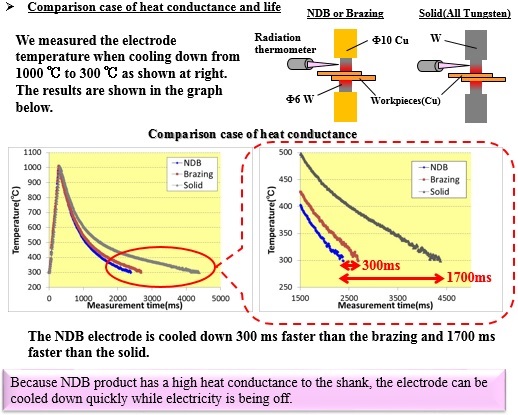

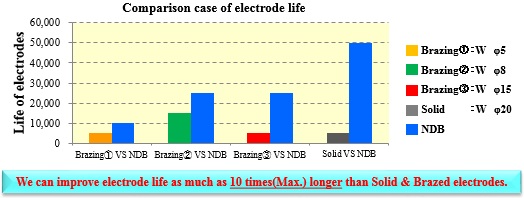

In addition, "NDB electrodes" that are directly bonded with the copper shank quickly release the heat into the shank when heating is stopped. They deliver great effects in terms of lifetime improvement, welding quality stabilization, and shot cycle improvement.

=> Electrodes whose hardness and electrical conductivity (IACS%) are improved through thermal treatments become blunt due to the repeated heating.

- We use copper welding or copper heat caulking, but the quality is not stable.

=> The point is to have the electrode generate heat!

=> It is the high-temperature range that chromium copper/alumina dispersion copper cannot endure.

Tungsten (W), molybdenum (Mo) and their alloy electrodes deliver high performance during resistance welding/heat caulking. They are also optimal for fusing electrodes and spot electrodes.

In addition, "NDB electrodes" that are directly bonded with the copper shank quickly release the heat into the shank when heating is stopped. They deliver great effects in terms of lifetime improvement, welding quality stabilization, and shot cycle improvement.

Required characteristics of the resistance welding electrode materials

1) Resistance to deformation under high temperatures

2) High heat and electrical conductivity

3) Low tendency to form alloys with the welded material or plating material

4) Resistance to oxidation in air

5) Low price

Resistance welding is an extremely delicate process, and it is difficult to make a sweeping statement regarding which electrodes are best suited for the process.

If you use a work piece made of materials other than copper or copper alloys, we recommend that you use copper electrodes, such as of chromium copper and alumina dispersion copper, and if you find these to be unsatisfactory in terms of their lifetime and performance, please try the tungsten-based electrodes mentioned below. Tungsten-based electrodes are recommended for resistance welding of copper wires, sheets, and so forth, including fusing.

Furthermore, tungsten-based electrodes are not specified in JIS, although they are included in Group B in ISO.

Classification by RWMA

The material types specified by the U.S. Resistance Welder Manufactures Association (RWMA) are as follows.

- RWMA-11 indicates copper tungsten, and corresponds to Eme C30A2 in our products.

- RWMA-13 indicates pure tungsten; we designate this as TR (Tungsten Rod).

Either of these materials can be bonded directly with the copper shank using our bonding technology, the NDB method. This method enables high-frequency welding, which is impossible to be carried out with the conventional press-fit or brazed materials.

This method also suppresses the consumption of the electrode itself, which leads to a decreased frequency of electrode replacement, and stabilization of the welding quality.

- RWMA-11 indicates copper tungsten, and corresponds to Eme C30A2 in our products.

- RWMA-13 indicates pure tungsten; we designate this as TR (Tungsten Rod).

Either of these materials can be bonded directly with the copper shank using our bonding technology, the NDB method. This method enables high-frequency welding, which is impossible to be carried out with the conventional press-fit or brazed materials.

This method also suppresses the consumption of the electrode itself, which leads to a decreased frequency of electrode replacement, and stabilization of the welding quality.

Introduction to the recommended electrode materials

- When the work piece is made of stainless steel, soft steel or low-alloy steel sheets (except for galvanized materials):

Ag-WC-based electrode materials (HS01, etc., in our materials), and Ag-W-based electrode materials (S35A2, etc., in our materials)

These are composite alloys of Ag which goes through little reaction with iron, chromium, nickel and so forth which are the main components of the welded material, and WC or W with high melting point and hardness. Specifically, the Ag-WC-based electrodes, with the lowest tendency for oxidation among all the tungsten-based electrodes, deliver excellent characteristics.

- When the work piece is made of copper or copper alloys:

Cu-W-based electrode materials (C20A2, etc.), pure Mo, and pure W

When the welded material is copper based, use of silver-based electrodes such as Ag-W and Ag-WC may result in welding between the electrode and the welded material through a eutectic reaction between silver and copper, which is not at all favorable. If the electrode itself needs to generate heat in processes such as heat caulking, pure Mo and pure W, which have relatively high specific resistance values and form solution with copper, are well suited.

★ We offer samples produced using the NDB method.

If you are willing to give us feedback on our test results, we offer free samples. Please feel free to contact us in this regard.

Ag-WC-based electrode materials (HS01, etc., in our materials), and Ag-W-based electrode materials (S35A2, etc., in our materials)

These are composite alloys of Ag which goes through little reaction with iron, chromium, nickel and so forth which are the main components of the welded material, and WC or W with high melting point and hardness. Specifically, the Ag-WC-based electrodes, with the lowest tendency for oxidation among all the tungsten-based electrodes, deliver excellent characteristics.

- When the work piece is made of copper or copper alloys:

Cu-W-based electrode materials (C20A2, etc.), pure Mo, and pure W

When the welded material is copper based, use of silver-based electrodes such as Ag-W and Ag-WC may result in welding between the electrode and the welded material through a eutectic reaction between silver and copper, which is not at all favorable. If the electrode itself needs to generate heat in processes such as heat caulking, pure Mo and pure W, which have relatively high specific resistance values and form solution with copper, are well suited.

★ We offer samples produced using the NDB method.

If you are willing to give us feedback on our test results, we offer free samples. Please feel free to contact us in this regard.

Welded materials and recommended electrode materials

Ceramic jigs

We also manufacture fine ceramic welding jigs.

Distribution in China

Shanghai Nippon Tungsten Sanyi Co., Ltd. is responsible for distribution of our products in the People's Republic of China.

Our sales personnel familiar with resistance welding electrodes will help you.

Our sales personnel familiar with resistance welding electrodes will help you.